MULTI VOLT(36V) Cordless Impact Driver Drill DV36DA

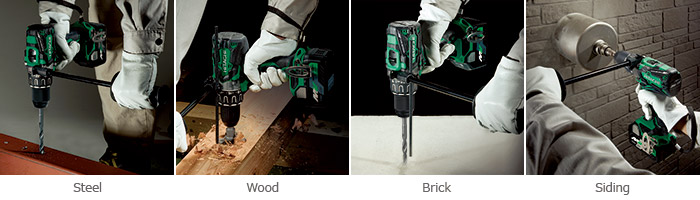

Enhanced Application Versatility

-

Able to drill a large hole in siding / ALC / plywood with a hole saw or self-feed bit, which results in greatly increased versatility.

Max. Capacity

| Steel | Wood | Brick | Siding | Wood Screws (Coach Bolt) |

|---|---|---|---|---|

| 16mm | 102mm | 20mm | 200mm | 12mm |

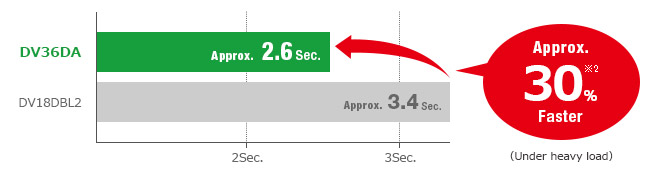

Fastest in class*1 Drilling Speed

-

Time to Drill a Hole

When drilling (in High Mode + Drill Mode) into SPF 76mm in thickness with a Ø38mm auger bit.

- As of July 2017. Among cordless impact driver drills made by leading power tool manufacturers.( Surveyed by Koki Holdings.)

- Vs. the 18V DV18DBL2 cordless impact driver drill.

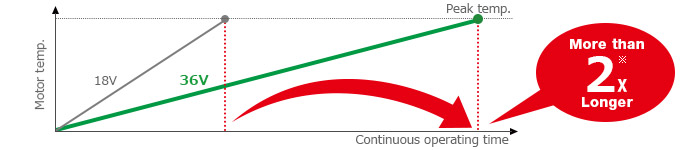

Significantly Prolonged Continuous Operation Time

-

Increasing the voltage of the Lithium-ion battery from 18V to 36V results in a slower temperature rise of the motor. Even when working continuously, the 36V MULTI VOLT tools are less likely to stop due to overheating than their 18V counterparts.

Motor Temp Rise under Constant Load

- Vs. the 18V DV18DBL2 cordless impact driver drill.

Significantly Prolonged Continuous Operation Time

-

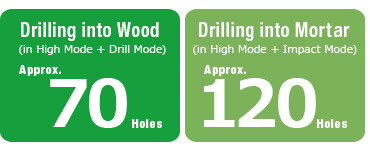

Drilling into Wood (in High Mode + Drill Mode): Approx. 70 Holes

(When drilling into SPF 76mm in thickness with a Ø38mm auger bit.)Drilling into Mortar (in High Mode + Impact Mode): Approx. 120 Holes

(When drilling 50mm deep holes into mortar with a Ø10 masonry drill bit)*The runtime is for reference purposes. It depends on the workpiece material and operating conditions.

Just as Compact as 18V Tools

-

The compact design with 204mm overall length provides excellent handling.

Double-Molded, Large Clutch Dial

-

The dial is clearly readable, even when well used. It’s also easy to grip for better handling.

Reactive Force Control

RFC

-

When the tool bit is suddenly overloaded during operation, the motor stops before the drill twists so as to minimize the danger of twisting the user’s arms.

Specifications

| Drill Chuck | 1.5 – 13mm (1/16" – 1/2") Keyless | |

|---|---|---|

| Capacity | Brick | 20mm (3/4") |

| Mild Steel | 16mm (5/8") | |

| Soft Wood | 102mm (4") | |

| Wood Screw | 12x100mm (15/32"x4") | |

| Machine Screw | 6mm (1/4") | |

| Battery Voltage | 36V | |

| No Load Speed | High | 0 – 2,100/min |

| Low | 0 – 500/min. | |

| Impact Rate | High | 0 – 31,500/min. |

| Low | 0 – 7,500/min. | |

| Max Torque | Hard | 138Nm (1,220in.-lbs.) |

| Soft | 64Nm (566in.-lbs.) | |

| Torque Setting | 2 – 8Nm (18 – 71in.-lbs.) | |

| Overall Length | 204mm (8") | |

| Weight*1 | 2.7kg (6.0lbs.) with BSL36A18 | |

| Vibration Total Values (triax vector sum)*2 |

Drilling into Metal | Vibration emission value ah, ID = 10.5m/s2 Uncertainty K = 1.5m/s2 |

| Standard Accessories*3 | 2 Batteries (BSL36A18)*4, Charger (UC18YSL3), Side Handle, Driver Bit, Battery Cover, Carrying Case | |

- Weight according to EPTA-Procedure 01/2003.

- Vibration total values (triax vector sum) determined according to EN60745.

- The included batteries and charger vary by country or area.

- Not compatible with the following existing batteries: BSL3620/3625/3626/3660, BSL18xx and BSL14xx series.