40mm (1-9/16") Rotary Hammer DH40MEY

- As of November 2014. Among rotary hammers made by leading power tool manufacturers, surveyed by Koki Holdings.

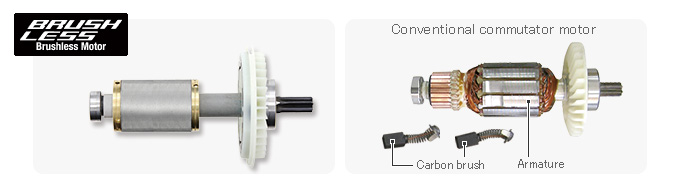

Maintenance-free

-

The product life cycle is significantly extended by eliminating troubles with armature burnout, layer short and commutator wear. Besides, no carbon brush replacement is required.

Fastest drilling speed in its class * even at voltage drops

Efficient brushless motor offers higher drilling performance even with an extension cord.

- As of November 2014. Among 40mm class rotary hammers made by leading power tool manufacturers, surveyed by Koki Holdings.

Compatible with engine generators

Designed to be powered by engine generators as well, thanks to Our original compact and high efficiency inverter circuit.

Highest *1 Demolition Performance and Fastest *1 Drilling Speed in its class

-

Acheived by high efficiency brushless motor and optimised hammering mechanism.

- As of November 2014. Among 40mm class rotary hammers made by leading power tool manufacturers, surveyed by Koki Holdings.

- A comparison of the model DH40MEY and the previous model DH40MRY. The results may vary depending on operating conditions.

- A comparison of the model DH40MEY and the previous model DH40MRY. Mean value for drilling into concrete with drill bits between 16mm and 40mm diameters. The results may vary depending on operating conditions.

- A comparison of the model DH40MEY and the previous model DH40MRY. The results may vary depending on operating conditions.

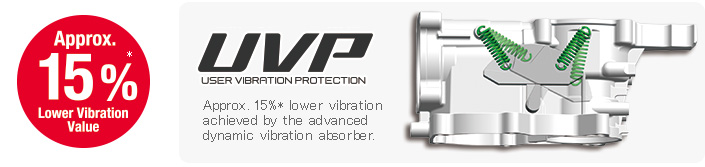

Our original, spring-type dynamic vibration absorber

-

Our original, spring-type dynamic vibration absorver with a weight and two springs moves in the opposite direction to the vibration direction of the main body. This results in reduced vibration and improved operating efficiency.

Vibration-absorbing handle

Vibration-absorbing mechanism with the transatory unit and the Neidhardt spring provides high vibration-absorbing effect.

The internal double-insulation construction with a very sturdy aluminium die-cast body and a plastic internal stator holder, is incorporated.

-

This makes the housing more rigid, significantly enhancing durability of the motor unit.

Push-button, constant speed control with variable speed

-

Equipped with a built-in electronic control circuit that can adjust the impact rate according to applications. Four-step impact rates can be selected by the rotation speed selector switch.

Display Lamp

No Load Speed 250 / min 330 / min 410 / min 500 / min Full Load Impact Rate 1,430 / min 1,900 / min 2,370 / min 2,850 / min

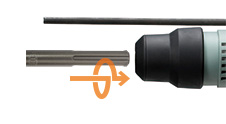

One push action for quick bit mounting

-

A bit can be mounted by simply inserting it into the tool holder.

Large change lever

-

Up-sized mode change lever is located on the top of the tool body for easier operation.

Large trigger switch

-

Up-sized, easy-to-grip trigger switch for more control.

Specifications

| Capacity | Drill bit: 40mm (1-9/16") Core bit: 105mm (4-1/8") |

|

|---|---|---|

| Power Input | 1,150W | |

| Bit Shank | SDS max | |

| No Load Speed | 250 - 500 / min | |

| Full Load Impact Rate | 1,430 - 2,850 / min | |

| Overall Length | 477mm (18-4/5") | |

| Weight (including side-handle) | 7.5kg (16.5 lbs.) | |

| Vibration Total Values (triax vector sum)* |

Hammer drilling into concrete |

Vibration emission value : ah, HD = 8.0m/s2 Uncertainty K = 1.5 m/s2 |

| Equivalent chiselling value | Vibration emission value : ah, CHeq = 7.3m/s2 Uncertainty K = 1.5m/s2 |

|

| Standard Accessories | Side Handle, Stopper, Rotary Hammer Grease A, Carrying Case | |

- The tri-axial vibration values were measured according to EN60745-2-6.